| MODELS | Screw diameter mm | L/D ratio | Extruder motors-KW | *Out put | Hose size range | ||

| Tubing Extruder |

Coating Extruder |

Tubing Extruder |

Coating Extruder |

Kg /hr | Diameter mm | ||

| TBH 5050 | 50 | 50 | 26:1 | 7.5 | 7.5 | 40-60 | 5 to 25 |

| TBH 5065 | 50 | 65 | 26:1 | 7.5 | 11.2 | 60-80 | 5 to 32 |

| TBH 6565 | 65 | 65 | 26:1 | 11.2 | 11.2 | 80-100 | 10 to 50 |

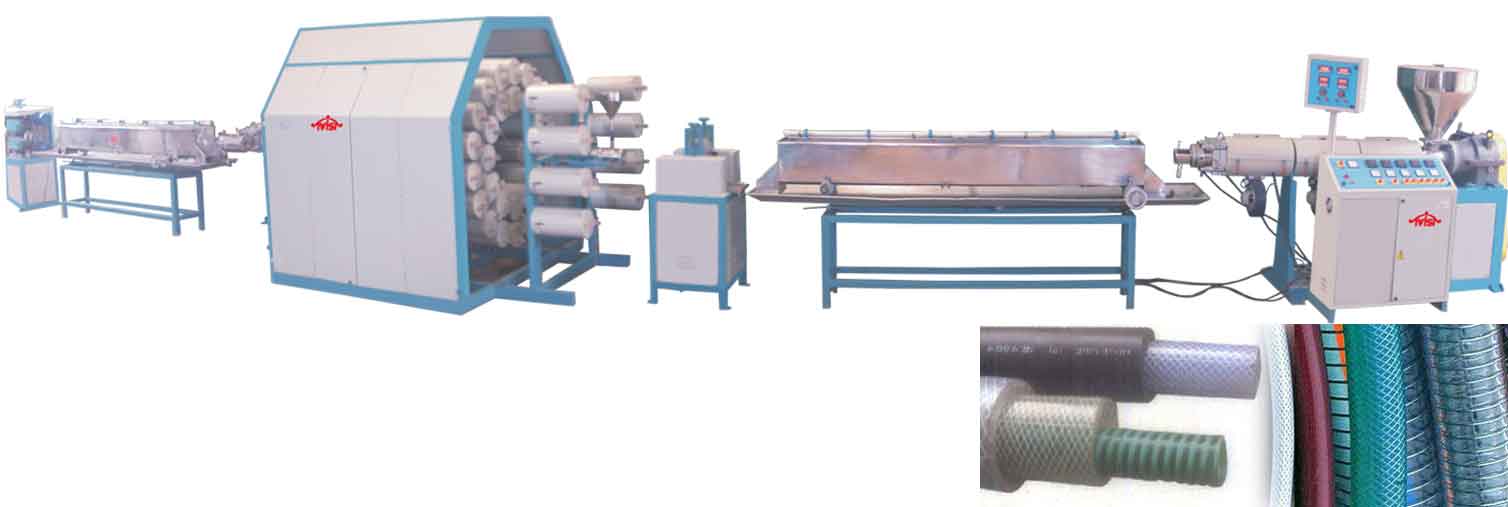

Suction Hose Plant

| MODELS | Screw diameter mm | L/D ratio | Extruder motors-KW | *Out put | Hose size range | ||

| RPVC Extruder |

Soft PVC Extruder |

RPVC Extruder |

Soft PVC Extruder |

Kg/hr | Diameter mm | ||

| TSH 5065 | 50 | 65 | 23:1& 26:1 | 7.5 | 11.2 | 60-80 | 19 to 100 |

| TSH 6565 | 65 | 65 | 23:1& 26:1 | 15.0 | 11.2 | 80-100 | 50 to 150 |

Note: Raw material for making braided hose is Soft PVC granules and for suction hose it is soft PVC granule as well as Rigid PVC compound. Soft PVC granules are available in market or can be made in house on extrusion plant. Braided and suction hoses can be made directly from dry blend PVC compound also.High Speed Mixer will be required for making PVC compound. Jockey Extruder has to be connected with the hose plant, if parallel colour line or strap is required on outer surface of the hose.